The Stone Demonstrator

Low-carbon construction requires a shift away from the abundant materials of the twentieth century. Future Observatory’s prototype of a stone structure tests one of Earth’s most abundant materials with new engineering know-how. This photo essay captures the process

Stone is one of the most abundant materials on Earth. Indeed, the entire crust of the planet is made of it. But as a building material it is, of course, extractive. An image of a stone city may well conjure another of a quarry. And yet concrete is far more extractive. While a stone building most likely stems from a single quarry, the process of making concrete requires numerous quarries. First the limestone is extracted and crushed. Then it is crushed again with clay, heated to 1,400 degrees and ground into cement powder which is mixed with various other materials such as gypsum, sulfates, gravel and sand. After all of that, water is added to turn the powder back into stone. Because of its intensive production, concrete has extremely high carbon emissions. By comparison, stone in its natural form is a low-carbon material.

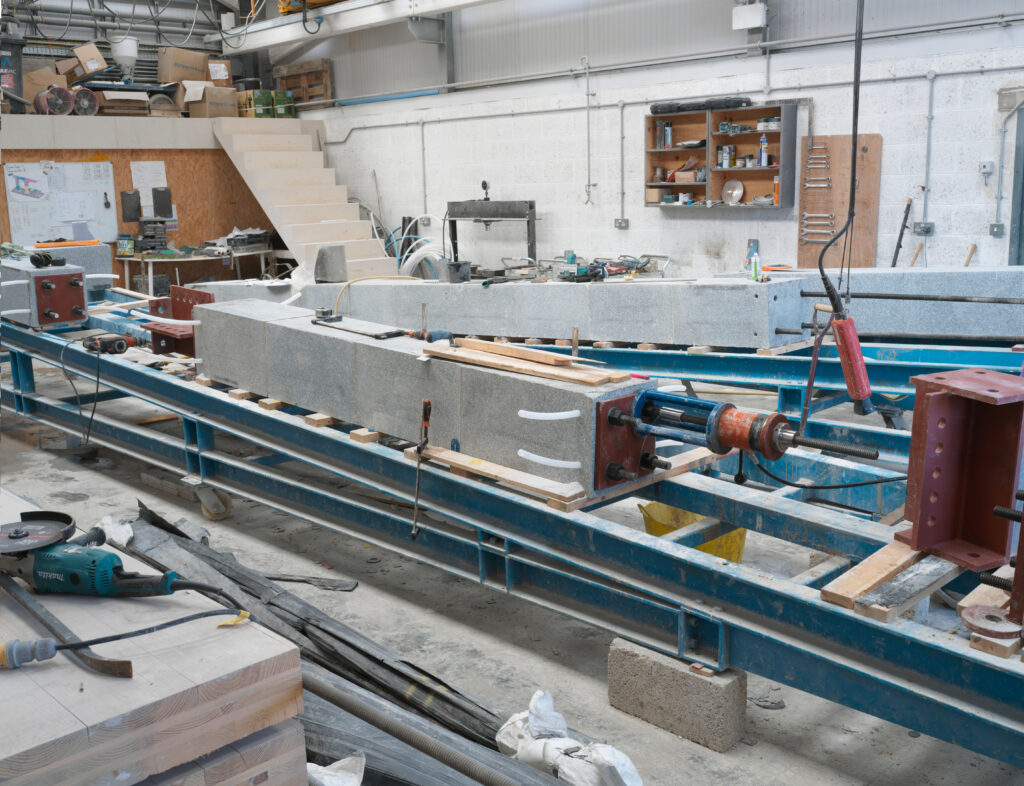

Future Observatory commissioned a full-scale prototype to engage the construction industry in the ultra-low-carbon potential of stone structures. Designed by architecture practice Groupwork with engineers Webb Yates and Arup, the Stone Demonstrator is a three-storey structure that uses a pre-tensioned stone frame. Stone blocks are joined by steel tendons and tightened together to form prefabricated beams and columns that are bolted together on site. This method emits 70 per cent less carbon than a reinforced concrete frame, and 90 per cent less than a steel frame. The system can also be disassembled and recycled in other buildings. Aside from the frame, the prototype also demonstrates two types of pre-tensioned stone floor slab, and a self-supporting facade of stone bricks. Given that a stone brick emits at least 90 per cent less carbon than a fired clay brick, and given that the UK uses 2.5 billion clay bricks each year, the climate benefits of stone bricks are potentially enormous.

The construction industry already uses vast quantities of stone in an ultra-processed form. The argument that the Stone Demonstrator makes is that it is far less damaging to use it in its raw form.

In this photo essay, Bas Princen documents the making of the stone columns and beams at The Stonemasonry Company’s site near Peterborough and the assembly of the Stone Demonstrator in London.