Energy and the Matter Problem

The dawn of infinite clean energy is beckoning, but we still have the problem of finite matter. What if energy ‘too cheap to meter’ means that we can finally close material loops, even for the mother of all problems: plastics

In 1856, when the son of Emperor Napoleon III was born, one of the gifts he received was a rattle made of a precious metal that was silvery, light and non-reactive: aluminium.

Whereas precious metals occur only in trace amounts, aluminium is one of the most abundant elements in the Earth’s crust. However, its metallic form is not found in nature, and it is extremely difficult to isolate the metal from the ore. It wasn’t until 1886 that two young scientists, working on opposite sides of the Atlantic, independently developed a way to do so. Known as the Hall–Héroult process, it is enormously energy-intensive, requiring bauxite ore (named after Les Baux, France, where it was mined) to be transformed into aluminium oxide and dissolved in a molten salt at about 1000 degrees Celsius. An electrical current is then run through the mixture to separate out the metallic aluminium. Even today, aluminium is sometimes described as ‘solid energy’ because of the sheer intensity of this process. In 1856, refining the metal would have required innovative technologies and great expense – making it a princely gift.

So how did aluminium become among the least precious of metals? To produce it cheaply and at scale, we needed not only the technology for smelting it, but also huge amounts of energy, the build-out of the refining capacity and access to aluminium ores and other raw materials. While the technology was provided by Hall and Héroult, most of the rest of the story was a matter of political will. In the US, this manifested in the construction of giant hydroelectric power stations such as the Hoover Dam, built as part of the New Deal’s widespread programme of federal infrastructure investment during the Great Depression. The stations provided the power for aluminium refineries built during World War II, which in turn supplied the factories producing fighter jets and bombers. In the second half of the twentieth century, expanded transportation networks and supply chains enabled a global mining industry to provide raw materials in huge quantities. Aluminium, despite the amount of energy needed to refine it, became, quite literally, disposable. The Hall–Héroult process is still in use today, and it is just as energy intensive. What has changed since its invention is that we have access to so much more energy, raw material and refining capacity, all at a scale and price that has taken aluminium production from prohibitively expensive to commonplace.

This example serves as a template for the possibilities available to us as we move into an era of clean, abundant and inexpensive renewable energy. The story of aluminium demonstrates how the development of new technology, powered by abundant energy, makes novel industrial processes economically viable. This means that we can start to recycle materials that previously made no economic sense to do so. Closing these material loops is the great opportunity of the clean energy era. But aluminium is also a cautionary tale: in humanity’s first energy transition, to fossil fuels, access to abundant energy was used to massively scale up production, with commensurate increases in extraction and pollution. The question we now face is: what will we decide to do with our abundant new energy sources?

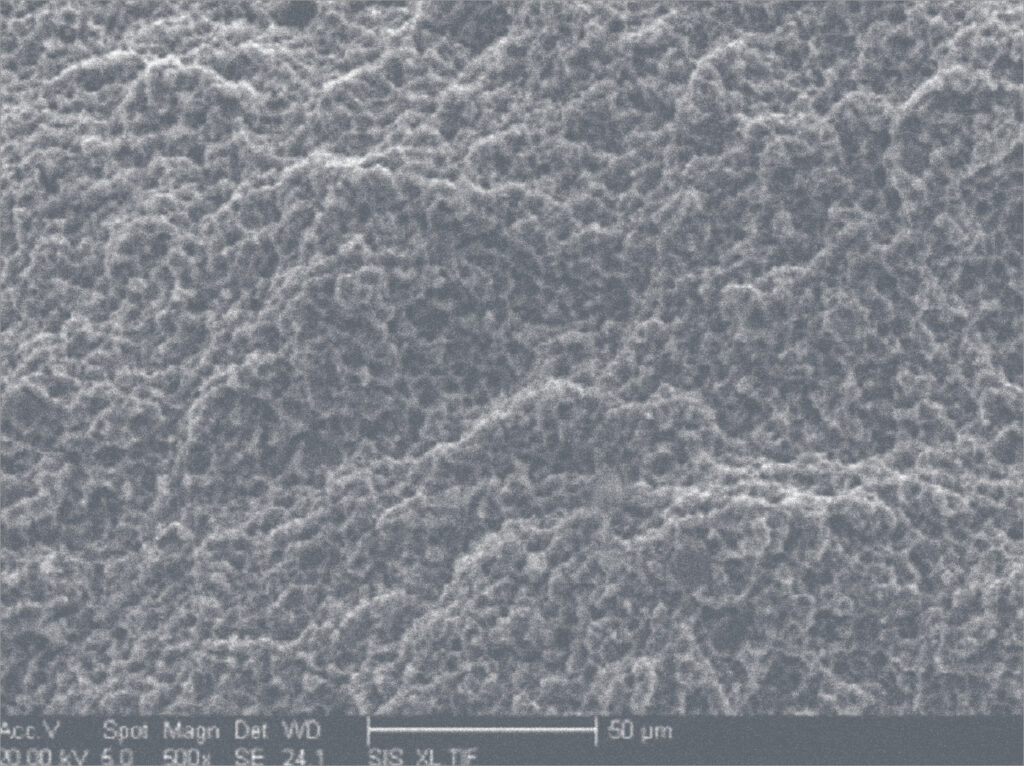

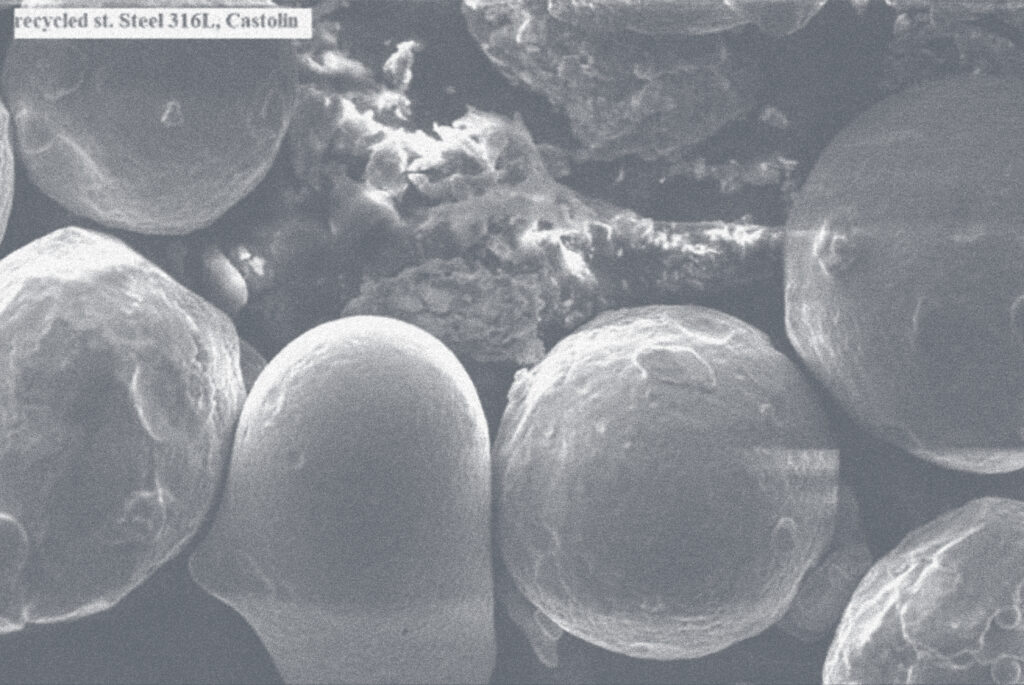

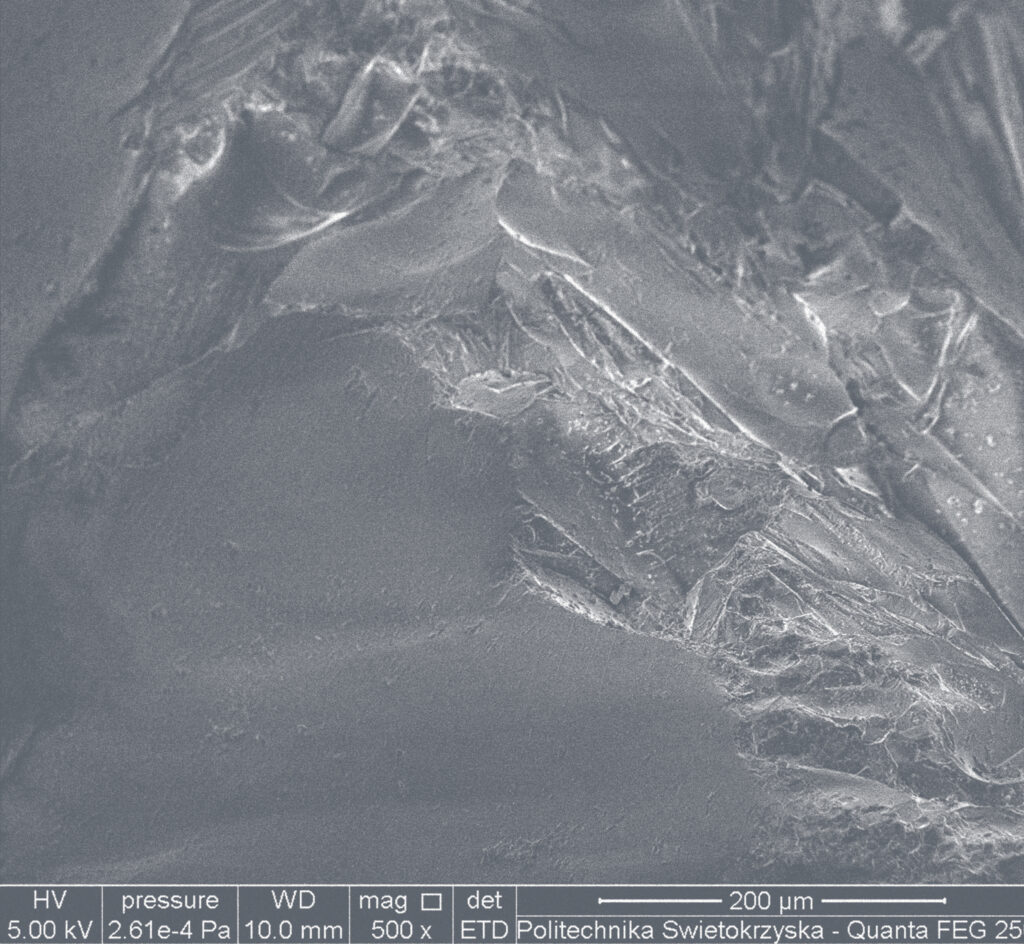

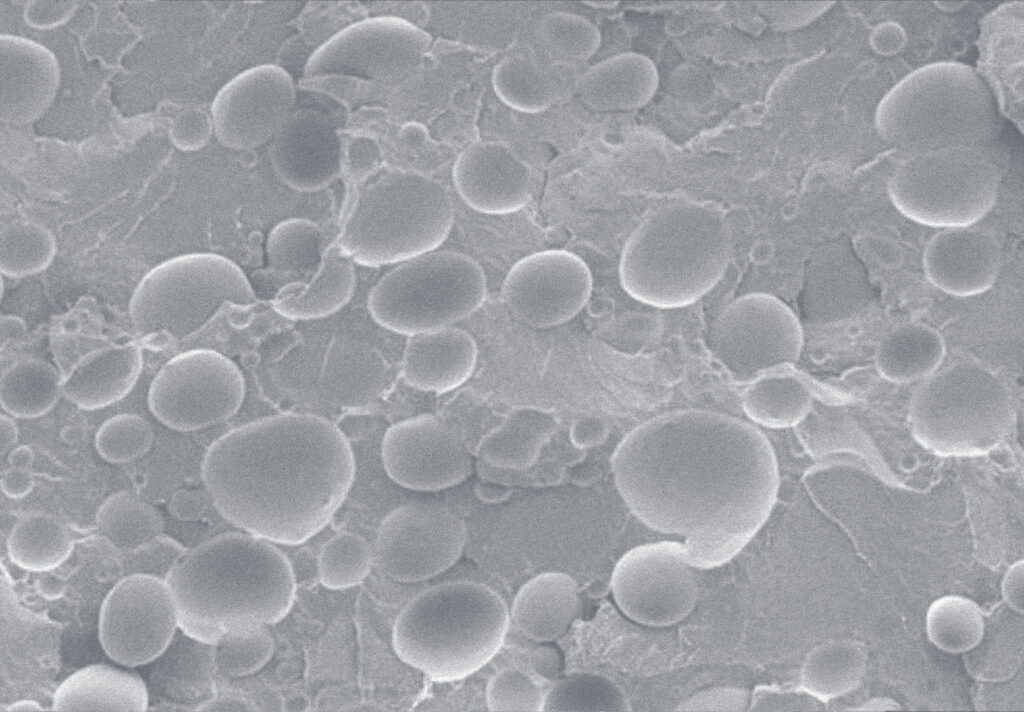

The economics of energy are a primary driver in determining which materials get recycled and which do not. Aluminium refining is so energy-intensive that it only takes about 5 per cent of that energy to recycle it, which is why most aluminium gets recycled. Melting steel for reuse takes a quarter of the energy of smelting it in the first place, and thus, equally, it makes economic sense to recycle steel. Not only can glass be melted to make new products, but crushed recycled glass (cullet) is a key ingredient in the manufacture of new glass. Mixing cullet into the sand and other raw ingredients lowers the melting temperatures and so reduces the amount of required energy, as well as the cost of production. Given their physical characteristics, it makes sense that steel, glass and aluminium all have fairly high rates of recycling.

But if we change the economics of energy, we change what materials we can recycle, and the ways in which we can close loops of usage and reuse. We are now in a position to do just this. In the past few decades, we’ve developed ways to effectively harness renewable energy at scale – inexpensive solar panels and the now-familiar three-vaned Danish wind-turbine design. Renewables like solar and wind have the same kind of economics as hydroelectricity, where once the system is built out, the incremental cost is close to zero: while capital, operating and distribution costs remain, you are no longer paying for the input energy on a per-joule basis. In a world powered entirely by renewables – a world that is now in sight – electricity may even achieve the long-held dream of being ‘too cheap to meter’.

We now have the potential to build out a world where all the energy we use is not just clean, but also both cheap and abundant.

What’s more, our home planet is absolutely awash in the energy that pours over it from the sun. If every human on Earth used the same amount of energy as those in the wealthiest, most economically developed countries, the total energy use of our species would still amount to only a fraction of a per cent of what arrives as sunlight. Every moment of every day, the incident solar energy reaching Earth dwarfs humanity’s total use. We now have the potential to build out a world where all the energy we use is not just clean, but also both cheap and abundant. And doing so would radically change the economics of energy. This is the powerful economic argument for decarbonising: replacing everything that is powered by fossil fuels with its electrical equivalent.

But, while we tend to think of ‘climate change’ or ‘the environment’ as the problem, there are actually two separate issues. The first is the energy problem – where do we get our energy from? The problem of producing clean energy at scale is now technically solved, even if, politically speaking, there is still urgent policy work to be done. But, while our planetary home might have an abundance of energy for our use, the earth is an almost entirely closed system for matter. Every atom that we use for human purposes – that is, every carbon atom that was extracted from a coal seam or drawn from an oil well – is still on earth. What we usually call ‘pollution’ is a shorthand way of saying that specific configurations of atoms are now someplace inconvenient or dangerous, whether it’s carbon dioxide in the atmosphere, microplastics in the ocean, forever chemicals (PFAS) in water supplies or even E. coli in sewage outfalls. This is the matter problem. Because our species gets most of our energy from combustion, the energy and matter problems have been inextricably linked. Access to energy necessarily entails moving carbon atoms from the surface to the atmosphere. Renewables break this linkage, making it possible for our species to get the abundant, inexpensive energy we need without the rearrangement and displacement of atoms that occurs in combustion. We can finally solve the energy problem without worsening the matter problem.

What’s more, we can use this new access to energy to address the matter problem. Just as the Industrial Revolution made new kinds of extraordinarily energy-intensive processes commonplace – like moving a tonne of metal to get a single person to work, or refining aluminium at scale – so too will inherently abundant and inexpensive renewables open the doors to processes that require even more energy. Some we know how to do already, but they’ve been too expensive (read: energy-intensive) compared to alternatives, like desalinating seawater to guarantee domestic water provision for the roughly one-third of humanity that lives within 50 km of a seashore. But what changing the economics of energy really enables is the closing of life-cycle loops for all kinds of materials, not just those whose recycling currently uses less energy than primary production. And rethinking what we do with plastics has to be near the top of this list.

Why is it so hard to recycle plastics? The industry has had the better part of a century to come up with thousands of specialised, useful plastics. Only a tiny minority of these lend themselves to mechanical recycling by being melted down or reused, and another small (albeit growing) handful are bioderived or biodegradable. This is largely because chemical companies have been incentivised to develop new plastics that can be sold, not to ensure they can be recycled. In practice, there’s almost no way to reclaim most plastics without first breaking them down to their chemical building blocks (by burning, for example), which can then be pieced back together. Combustion produces energy – it’s why the incineration of trash can be used to produce heat and electricity – and, conversely, chemically reassembling the atoms into new plastics requires energy. As long as that energy is coming from fossil fuels, it won’t make economic sense to burn them for the energy to chemically recycle plastics when you can always just start with freshly extracted oil and gas. So there has been little incentive to develop the necessary technologies.

If, instead, the energy comes from solar or other renewable sources, we open up new possibilities for reclaiming the atoms in plastics, even ones that can’t be recycled by conventional means. It becomes economically feasible to reassemble carbon dioxide and water back into useful molecules if you can power the process with renewable energy – you’ll need a lot of it, but it’s cheap and abundant. You can even use the atoms that are already in the atmosphere as your feedstock to make new complex molecules (that’s what plants are, after all – solar-powered chemical factories that turn carbon dioxide, water and trace elements into polymers like cellulose and lignin, with oxygen as a byproduct). Hall and Héroult figured out a process to refine aluminium using electricity even before it was widely available; the necessary technologies for making plastic from the carbon in the air are active areas of research, development and commercialisation, now that the transition to renewable energy that will make them economically viable is within reach. Companies like Twelve (twelve.co) are building out pilot plants for new technologies that catalyse reactions that turn atmospheric carbon dioxide and water into long molecules like polymers and hydrocarbon chains (that is, fuels), powered by renewables. This is the technology that solves the previously intractable problem of closing the loop on existing plastics: we can recycle them chemically, by pulling them apart and putting them back together again. And it demonstrates how we can begin to think about reusing all the atoms that we use, not just the ones that are easy or convenient to recycle. It’s not the only way we can do it – we can develop new ways of breaking down existing plastics into reusable building blocks, or design new plastics. But by recognising the economics of energy, we can open up new pathways not just for plastics but for all the materials we make and how we recycle them.

Returning to the case of aluminium, if we want to roll out new industrial processes at scale, we need three things: access to energy, technological know-how and large-scale investment in these systems. That’s the template, but the cautionary tale we can take from aluminium is this: if we again use those three elements to just turbocharge extraction – like mining lithium globally to use in electronics designed to quickly become obsolete – rather than for the recovery of post-consumer materials, we’ll dig ourselves ever deeper into the problem of matter, even if we solve the energy problem.

While the economic upside of transitioning to renewable energy is now largely self-evident, the economic upside of using this energy to close material loops is not – at least not in the ways we currently think about ‘economics’. There is no sustainable future where we address the energy side of fossil fuels without using that energy to rethink how we handle materials. The best reason to go as hard as we can into renewable energy is not just to power data centres and EVs – it’s to bring our technological society in line with the physical reality of our planet, where energy is abundant, but every atom has to go somewhere. If we get good at closing material loops – not just for plastics but for everything – and put renewable energy to work to repurpose every atom in every artefact at the end of its useful life, then we can have every thing that we need to interface with the world, with the understanding that when we’re done with it, it’ll get torn apart into its constituent atoms and used as feedstock to make the next thing.

We can envision a world where everything that we’ve ever pulled out of the ground – every carbon atom, every aluminium, gold and lithium atom – gets endlessly reused in useful ways, where the only input is clean energy. If we build out this world – a world where everyone has all the energy they need, and we use that energy to mitigate pollution – we’ll solve climate change as a side effect.

This is a future that depends on recognising what we have in abundance – energy, human ingenuity and motivation – and applying it to what is truly finite: the atoms that we need to make things and the places they can be put when we’re done with them. This world has little to do with economics, GDP or growth, and everything to do with living in a planet-sized terrarium. It doesn’t need any wishful thinking about mining asteroids or miraculous new technologies. It’s about making a collective decision to do what is now technologically possible: to align our physical systems with our planetary reality.